The production of high-performance, lightweight structures has been revolutionized by a sophisticated composite manufacturing process known as Filament Winding.

This technique has become key in many industries. It’s great for making complex shapes with high precision.

There are three main methods in Filament Winding: hoop, helical, and polar winding. Each has its own benefits in making composite materials.

Knowing these techniques is vital for manufacturers. It helps them use the best of composite materials in their products.

The Science Behind Filament Winding

Filament winding is a method where filaments are wrapped around a mandrel. It’s key in making strong composite structures. This method is widely used in the aerospace field.

Definition and Fundamental Concepts

Filament winding involves wrapping resin-impregnated filaments around a mandrel. It aims to create a strong and durable composite structure. The Filament Winding machine ensures the filaments are wound with precision. This leads to consistent and high-quality products.

Historical Development of Filament Winding

Filament winding started in the 1940s. It saw major growth in the 1950s and 1960s, mainly in the Aerospace industry. It was first used to make rocket motor cases and other high-performance parts. Today, thanks to better Filament Winding equipment, it can create complex shapes and large structures.

| Decade | Development | Industry Impact |

|---|---|---|

| 1940s | Initial development of filament winding | Aerospace |

| 1950s-60s | Significant advancements in technology | Aerospace, Defense |

| 1970s-80s | Expansion to other industries | Automotive, Energy |

Core Components of the Filament Winding Process

Understanding the core components of the filament winding process is key for making top-notch composite materials. This process involves several important elements that work together. They help create high-quality products.

Delivery System and Tensioning Mechanisms

The delivery system feeds the fiber material to the mandrel. Tensioning mechanisms make sure the fibers are wound correctly. Proper tension control is vital for even fiber distribution and avoiding defects.

A good delivery system and tensioning mechanism are essential for consistent winding. They use precision tension control devices to adjust tension in real-time.

Mandrel Design and Considerations

The mandrel is the mold where the composite material is wound. Mandrel design greatly affects the product’s shape and surface finish. It must handle the winding stresses and provide the right surface.

Different mandrel materials and designs are needed for various applications. For example, mandrel surface treatment can greatly affect the product’s finish.

| Mandrel Material | Application | Surface Finish |

|---|---|---|

| Steel | High-pressure vessels | Smooth |

| Aluminum | Aerospace components | Polished |

| Composite | Sports equipment | Textured |

Control Systems and Programming

Modern filament winding machines use advanced control systems and programming. These systems control winding speed, tension, and pattern precisely.

Computer Numerical Control (CNC) systems are often used for accurate control. Advanced programming helps create complex shapes and patterns.

Experts say, “Advanced control systems and precise mandrel design are essential for high-quality composites through filament winding.”

“The future of composite manufacturing depends on precise control over filament winding. This ensures consistent quality and performance.”

Materials Selection for Filament Winding

Choosing the right materials is key in filament winding. It affects how well the final product works and lasts. The materials used in filament winding greatly impact the final composite’s properties and performance.

Reinforcement Fibers: Glass, Carbon, and Aramid

Reinforcement fibers are essential in filament winding. They add strength and stiffness for different uses. Glass fibers are often picked because they’re affordable and strong enough for many needs.

Carbon fibers are better for high-strength and light applications, like in aerospace. Aramid fibers are great for withstanding shock and vibrations.

| Fiber Type | Tensile Strength | Elastic Modulus | Density |

|---|---|---|---|

| Glass | 2000-4000 MPa | 70-80 GPa | 2.5 g/cm³ |

| Carbon | 4000-6000 MPa | 200-400 GPa | 1.8 g/cm³ |

| Aramid | 3000-4000 MPa | 70-130 GPa | 1.44 g/cm³ |

Matrix Systems: Thermosets vs. Thermoplastics

The matrix system holds the fibers together in filament winding. It helps transfer loads and protects against environmental factors. Thermoset matrices, like epoxy and polyester, are popular for their strong bond with fibers and chemical resistance.

Thermoplastics are less common but offer benefits like recyclability and toughness. The choice between thermosets and thermoplastics depends on the application and manufacturing needs.

Additives and Modifiers

Additives and modifiers improve specific properties of the composite. They can include fillers for cost savings and stability, tougheners for impact resistance, and UV stabilizers for weather protection. The right additives and modifiers depend on the material’s use and conditions.

In summary, picking materials for filament winding is complex. It involves balancing mechanical properties, cost, and application needs. By carefully choosing fibers, matrices, and additives, manufacturers can create high-quality composites for various industries, including aerospace.

Hoop Winding Technique in Detail

In the world of composite materials, hoop winding is a key technique. It involves winding fibers at a high angle, usually near 90 degrees, to the mandrel axis. This method is essential for making parts with strong circumferential strength.

Principles and Mechanics of Hoop Winding

Hoop winding works by aligning fibers for maximum strength and stiffness in the circumferential direction. It’s great for things like pressure vessels. The process requires controlling the winding angle and tension for the best fiber placement.

For more on filament winding, check out this resource.

Process Parameters and Optimization

Important parameters in hoop winding include tension, fiber volume fraction, and speed. Getting these right is key for the right mechanical properties and fewer defects. Keeping tension even is important to avoid fiber misalignment and ensure resin is spread evenly.

Optimization Techniques:

- Tension control

- Fiber volume fraction management

- Winding speed adjustment

Structural Properties and Performance Characteristics

Parts made with hoop winding have great strength and stiffness in the circumferential direction. This makes them perfect for applications needing resistance to internal pressure. By choosing the right materials and process settings, hoop winding can be tailored for specific needs.

It’s widely used for making pressure vessels, pipes, and other cylindrical parts.

“The hoop winding technique allows for the creation of composite materials with tailored mechanical properties, improving their performance in tough applications.”

Helical Winding Technique Explained

In the world of filament winding, Helical Winding is very versatile. It involves winding fibers at an angle to the mandrel axis. This makes it great for creating complex shapes, which are key in many fields, like the Aerospace industry.

Principles and Mechanics of Helical Winding

The Helical Winding method winds fibers around a mandrel at a certain angle. This angle, called the winding angle, is very important. It decides how strong the final product will be. The process needs careful control to get the right thickness and fiber direction.

The filament winding process in Helical Winding winds fibers continuously. This gives the structure great mechanical strength. It’s perfect for making round or spherical shapes.

Winding Angle Considerations and Effects

The winding angle greatly impacts the product’s strength and performance. A smaller angle means more longitudinal strength. A bigger angle means more hoop strength. So, picking the right angle depends on what the product needs.

- Winding angle affects longitudinal and hoop strength.

- Optimal winding angle depends on the application.

- Precise control over winding angle is critical.

Structural Properties and Performance Characteristics

The strength of components made with Helical Winding depends on several things. These include the type of fiber, the winding angle, and the resin used. This method is great for making things that are strong but light, which is important in the Aerospace industry.

Helically wound structures also do well against buckling. They last longer under tough loads.

Polar Winding Technique Analysis

Polar winding wraps fibers around the ends of a mandrel. It’s great for making strong composite materials. These materials are used in high-performance fields.

Principles and Mechanics of Polar Winding

This technique winds fibers around the mandrel’s ends. It makes complex shapes with better strength. The process controls the angle and tension for the best results.

- Precise control over winding angle and tension

- Creation of complex geometries

- Enhanced mechanical properties

End Closure Design and Considerations

Designing the ends is key in polar winding. It affects how well the product works. The shape, material, and how it fits with the rest matter a lot.

Key considerations:

- Shape of the end closures

- Material selection

- Integration with the composite structure

Structural Properties and Performance Characteristics

Polar winding makes materials stronger and more durable. The product’s performance depends on the winding, fiber, and matrix.

By adjusting these, makers can create parts for aerospace and storage tanks. These parts have the right properties for their jobs.

Comparative Analysis of Filament Winding Techniques

Different filament winding techniques have unique benefits for structure and efficiency. The method chosen greatly affects the product’s quality and the cost of making it.

Structural Performance and Mechanical Properties

The strength and mechanical properties of filament-wound parts vary by technique. For example, hoop winding is great for pressure vessels because it offers strong circumferential strength. On the other hand, helical winding lets you adjust angles for better performance under different loads.

Here’s a table comparing the mechanical properties of different techniques:

| Winding Technique | Circumferential Strength | Axial Strength |

|---|---|---|

| Hoop Winding | High | Low |

| Helical Winding | Variable | High |

| Polar Winding | Low | High |

Production Efficiency and Cost Factors

The efficiency and cost of filament winding depend on the technique. Hoop winding is quicker and cheaper for making round parts. But helical winding is more flexible for complex shapes, though it might cost more.

Costs include raw materials, machine time, and labor. Knowing these costs helps manufacturers choose wisely.

Selection Criteria for Different Applications

Choosing a filament winding method depends on the application and needed product properties. For the aerospace industry, advanced helical winding is often used for its strength and lightness.

Manufacturers must think about the mechanical needs, production volume, and budget when picking a technique.

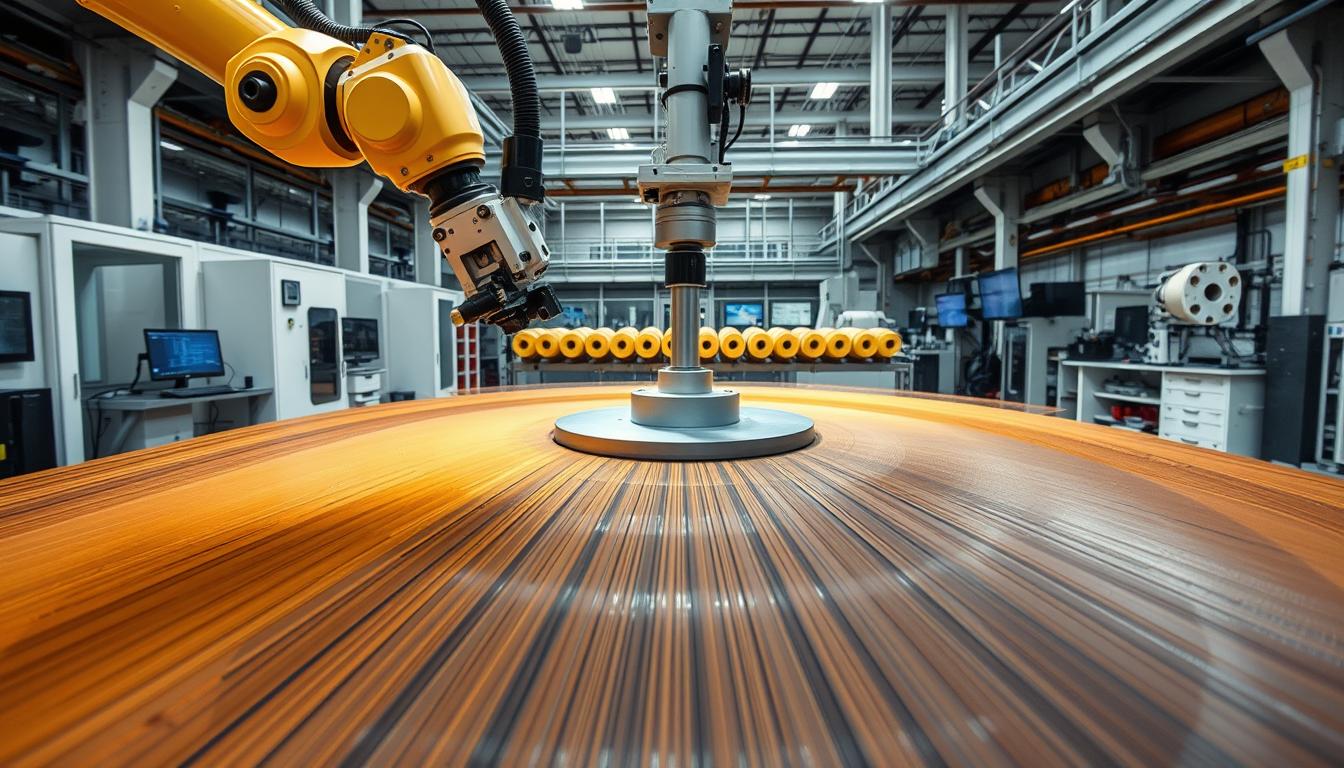

Advanced Filament Winding Equipment

Advanced filament winding machines are key in modern composite making. They help create complex shapes with great precision.

New filament winding tools have made making composites better and more precise. Today’s machines have smart controls and precise parts. This lets them make complex shapes and big structures.

2-Axis vs. Multi-Axis Winding Machines

Filament winding machines are split into 2-axis and multi-axis types. 2-axis machines work for simple shapes and are cheaper. Multi-axis machines can make complex shapes and are more flexible.

| Machine Type | Capabilities | Applications |

|---|---|---|

| 2-Axis | Simple geometries, cost-effective | Tanks, pipes |

| Multi-Axis | Complex shapes, high precision | Aerospace components, complex structures |

Computer Numerical Control (CNC) Systems

CNC systems have changed filament winding by giving exact control. They make complex patterns and make the process more consistent.

“The integration of CNC systems in filament winding machines has significantly enhanced the precision and repeatability of the process, allowing for the production of high-quality composite parts.”

Emerging Technologies in Winding Equipment

New tech like robotics and AI are being added to filament winding tools. These updates will make making composites even better and more efficient. They will be very important for the future of composite making.

Surface Finish and Quality Control

In the world of composite manufacturing, the surface finish and quality control are key. They ensure the parts made from filament-wound materials are strong and look good. The surface finish affects how well the parts work and how long they last.

Factors Affecting Surface Quality

Many things can change how good the surface of filament-wound parts looks. The type of fibers used, the matrix system, and how the parts are made all play a role. Reinforcement fibers like glass, carbon, and aramid have unique properties that impact the surface finish. For example, carbon fibers usually make a smoother surface than glass fibers.

The winding tension and resin content are also important. The right tension makes the fibers lay flat, and the right amount of resin makes the surface smooth.

Common Defects and Their Prevention

Some common problems with filament-wound parts include surface porosity, fiber waviness, and resin-rich areas. Surface porosity can be lessened by adjusting the resin content and making sure the fibers are well-impregnated. Fiber waviness can be avoided by keeping the winding tension steady and placing the fibers accurately.

- Optimize resin content to prevent surface porosity

- Maintain consistent winding tension to prevent fiber waviness

- Ensure accurate fiber placement for uniform surface quality

Testing and Inspection Methods

There are many ways to check the surface finish and quality of filament-wound parts. These include looking at them visually, measuring the surface roughness, and using non-destructive testing (NDT) like ultrasonic testing.

Visual inspection gives a first look at the surface quality. Surface roughness measurement gives a number to show how smooth it is. Ultrasonic testing finds hidden defects inside the part.

Industrial Applications of Filament Winding

Filament winding is used in many industries, from making aerospace parts to sports equipment. It’s great for creating strong, yet light, structures.

Aerospace and Defense Components

In the aerospace field, filament winding makes parts that are both strong and light. This is key for rocket motors and aircraft bodies. Advanced composites from this method help planes use less fuel and last longer.

Pressure Vessels and Storage Tanks

Filament winding is key for making tanks and vessels for chemicals, oil, and water. It makes these containers strong and light. The corrosion resistance of these materials also makes them last longer.

Sports Equipment and Recreational Products

The sports world benefits from filament winding too. It makes things like bike frames, golf clubs, and fishing rods. These items are strong, light, and can be made just right for athletes.

Infrastructure and Construction Applications

In construction, filament winding helps make materials for fixing and building. It’s used for bridge repair and making composite rebar for concrete. These materials are durable and last longer, saving on upkeep costs.

Process Optimization and Manufacturing Considerations

In composite manufacturing, making the filament winding process better is key. To get consistent quality and performance, you need to understand the process well. This includes knowing what affects it.

Tension control and fiber placement are very important. The tension during winding affects how strong the product is. Getting the tension right means the fibers are just right, not too loose or too tight.

Tension Control and Fiber Placement

Keeping the tension the same during winding is essential. Tensioning systems help by adjusting tension as needed. Also, placing the fibers correctly is key to following the design.

| Aspect | Importance | Optimization Technique |

|---|---|---|

| Tension Control | High | Advanced Tensioning Systems |

| Fiber Placement | High | Precision Placement Technology |

Resin Content and Impregnation

The resin’s role is also critical. It holds the fibers together and helps transfer loads. Finding the right amount of resin is important for good impregnation and fewer voids.

“The key to successful composite manufacturing lies in the optimal balance between resin and reinforcement fibers.” – Expert in Composite Materials

Curing Cycles and Post-Processing

The curing cycle greatly affects the material’s final properties. Optimizing curing means controlling temperature, pressure, and time. This ensures the material is fully cured and has less stress. Post-processing, like machining and finishing, also affects the product’s quality.

Improving these key areas of process optimization can greatly enhance product quality and performance. As demand for composites grows, so does the need for better process optimization. This is true across industries like aerospace and energy.

Case Studies: Successful Implementation of Winding Techniques

Several case studies show the good and bad of using filament winding. They cover different fields, proving filament winding’s value in making complex parts.

Aerospace Component Manufacturing

The aerospace field has grown thanks to filament winding. For example, filament-wound composite structures are in rocket and satellite parts. They are strong yet light, and don’t get worn out easily.

One example is composite overwrapped pressure vessels (COPVs) for space. They make things safer and lighter.

High-Pressure Gas Cylinders

Filament winding makes high-pressure gas cylinders. These cylinders hold gases like hydrogen and oxygen. They are light but can handle very high pressures.

A study on type IV gas cylinders showed its success. It proved helical winding makes strong and safe cylinders.

Wind Energy Applications

In wind energy, filament winding makes wind turbine blades and parts. It lets us make longer, better blades. This means more energy for us.

A study on a wind turbine maker showed its benefits. It found less waste and better blade performance with filament winding.

| Industry | Application | Benefits |

|---|---|---|

| Aerospace | Component Manufacturing | High strength-to-weight ratio, resistance to fatigue |

| Energy Storage | High-Pressure Gas Cylinders | Lightweight, high pressure resistance |

| Wind Energy | Wind Turbine Blades | Increased efficiency, reduced material waste |

Future Trends in Filament Winding Technology

Future trends in filament winding will be shaped by new hybrid techniques, digital twin simulations, and a focus on sustainability. These advancements will boost efficiency, performance, and environmental sustainability in the industry.

Hybrid Winding Techniques

Hybrid winding techniques are becoming a big trend. They mix different methods to create parts with better mechanical properties. This makes it easier to customize parts for specific needs.

Digital Twin and Simulation Advancements

Digital twin technology and advanced simulations are changing the filament winding industry. They allow for real-time monitoring and predictive maintenance, cutting down on downtime. Simulations also help optimize winding patterns without needing physical prototypes, saving time and money.

“The use of digital twins in filament winding can reduce production costs by up to 20% and improve product quality by 15%.” – Industry Expert

Sustainability and Recycling Considerations

Sustainability is key in the filament winding industry now. There’s a push to reduce waste and make recycling better. Companies are using recycled materials and making production greener. This reduces environmental impact and boosts the industry’s image.

| Trend | Description | Benefits |

|---|---|---|

| Hybrid Winding Techniques | Combining different winding methods for superior properties | Greater flexibility, customization |

| Digital Twin and Simulation | Real-time monitoring and predictive maintenance | Improved efficiency, reduced downtime |

| Sustainability and Recycling | Reducing waste and improving recyclability | Minimized environmental impact, enhanced compliance |

Conclusion

Filament winding is a key method for making top-notch composite structures. It’s used a lot in the aerospace field and others. This method wraps continuous fibers, like carbon or glass, around a mandrel to form complex shapes.

There are different techniques, like hoop, helical, and polar winding. Each has its own benefits and fits various needs. Knowing how these work helps makers improve their work and make better composite materials.

Thanks to advanced tools, like multi-axis winding machines and CNC systems, filament winding has gotten even better. As the need for strong composites keeps rising, filament winding will play a bigger role. This will lead to new ideas and improvements in the field.