Fermenter design is key in many fields like pharmaceuticals, food, and chemicals. A fermenter or bioreactor helps create the right conditions for making biological products.

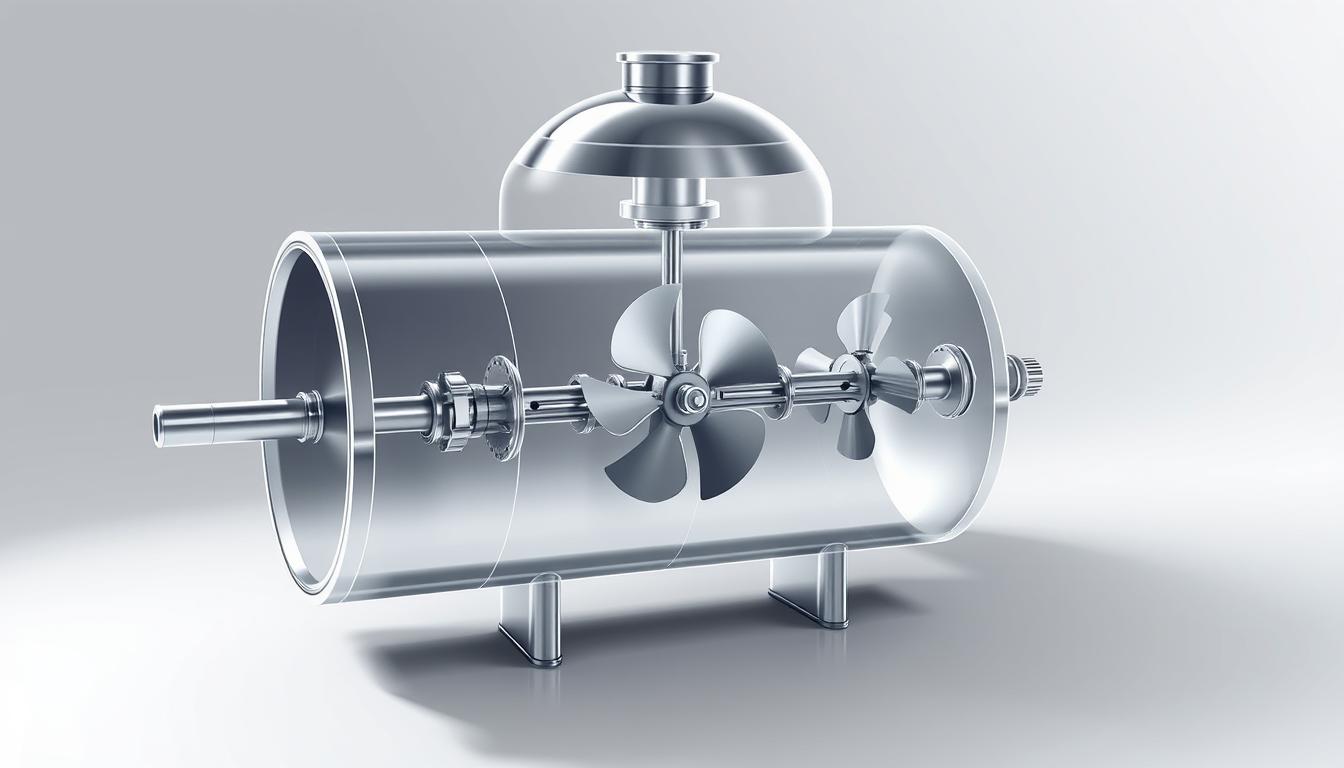

The design of a fermenter with three multi-bladed agitators is vital for better fermentation. Agitators mix and aerate the culture medium. This ensures microorganisms get enough oxygen and nutrients.

The industrial fermenter is engineered for specific needs. This includes controlling temperature, managing pH, and mixing. Good fermentation tank design is essential for high-quality products.

Understanding Industrial Fermentation Processes

Fermentation uses microorganisms to make products in many industries. It creates chemicals, medicines, and food items. The design of fermenter vessels and bioreactor design is key to these processes.

Biological and Chemical Foundations of Fermentation

Fermentation relies on microorganisms’ metabolic activities. They turn substrates into products through biochemical pathways. Knowing these steps helps improve fermentation and product yields.

A customized fermenter can make these processes more efficient. It provides the best conditions for microorganisms.

Industrial Applications of Fermentation Technology

Fermentation technology is used in many ways, like making biofuels, vaccines, and food additives. Its scalability and efficiency are vital in these fields. Advances in bioreactor design and fermenter vessel technology boost innovation and productivity.

Using multiple agitators in fermenters can enhance mixing and mass transfer. This leads to better product quality and yield. Tailored solutions, like customized fermenter designs, are essential for meeting industrial needs.

Fermenter Design: Core Principles and Evolution

Industrial fermentation equipment has evolved a lot. Today, designs aim to improve performance and reduce environmental harm. This change comes from advances in materials science and technology.

Historical Development of Industrial Fermenters

The first large-scale fermentation processes started in the early 20th century. Back then, fermenters were just simple batch tanks. They had little agitation and no temperature control.

Later, these designs evolved into more complex systems. They included advanced agitation, temperature control, and sterilization.

The use of stainless steel fermenters was a big step forward. Stainless steel is great because it resists corrosion, is easy to clean, and lasts long.

Key Components of Modern Fermentation Systems

Modern fermentation systems have several important parts. These include:

- Agitation systems for even mixing and oxygen distribution

- Temperature control systems to keep the right temperature

- Aeration systems for oxygen in aerobic processes

- Monitoring and control systems to manage the process

The design of these parts is key to the fermenter’s success. For example, the agitator’s design affects mixing and oxygen transfer.

Design Parameters and Performance Metrics

Designing a fermenter involves several important factors. These factors include:

| Design Parameter | Description | Performance Metric |

|---|---|---|

| Agitation Speed | Speed at which the agitator operates | Mixing Efficiency, Oxygen Transfer Rate |

| Temperature Control | Ability to maintain optimal temperature | Temperature Uniformity, Product Yield |

| Aeration Rate | Rate at which oxygen is supplied | Oxygen Transfer Rate, Cell Growth Rate |

By fine-tuning these design factors, manufacturers can boost their fermentation process. This leads to better products and lower costs.

The Critical Role of Agitation in Fermentation

In industrial fermentation, agitation is key to success. It makes sure microorganisms spread out evenly. This ensures they get the nutrients and oxygen they need.

Mixing Dynamics in Fermentation Processes

Mixing is vital in fermentation. It affects how well nutrients and microorganisms mix. Multi-bladed agitators help by creating flows that avoid dead spots.

| Agitator Type | Mixing Efficiency | Power Consumption |

|---|---|---|

| Multi-Bladed | High | Moderate |

| Single-Blade | Low | Low |

| Dual-Blade | Moderate | High |

Impact of Agitation on Yield and Product Quality

Agitation greatly affects how much product you get and its quality. Good agitation keeps microorganisms happy. This means better yields and consistent quality.

But, bad agitation can cause problems. It might lead to less product and quality issues. To fix this, using the right customized fermenter designs helps a lot.

Multi-Bladed Agitators: Technology Overview

Multi-bladed agitators are key in fermenter vessel design. They improve mixing and mass transfer. This is vital for making sure the fermentation broth is evenly mixed, which is important for the quality of the final product.

Evolution of Agitator Technology

The technology of multi-bladed agitators has changed a lot over time. At first, simple designs were used. But as fermentation processes got more complex, so did the agitator designs. Today, agitators are made to mix better, use less power, and protect cells or products.

Types of Multi-Bladed Impellers

There are many types of multi-bladed impellers for fermentation tank design. Each has its own features and uses. Here are a few common ones:

- Rushton turbines, known for their high shear rates and excellent gas dispersion capabilities.

- Pitched-blade turbines, which offer a balance between mixing and shear.

- Hydrofoil impellers, designed for low shear and high flow rates.

The right impeller depends on the fermentation process needs. This includes the broth’s viscosity and the needed aeration level.

| Impeller Type | Shear Rate | Flow Rate | Application |

|---|---|---|---|

| Rushton Turbine | High | Moderate | Gas dispersion, high shear processes |

| Pitched-Blade Turbine | Moderate | High | General mixing, moderate shear |

| Hydrofoil Impeller | Low | High | Low shear, high flow applications |

Material Considerations for Agitator Construction

The materials for multi-bladed agitators are very important. They need to be durable and perform well. Stainless steel and titanium are common choices. They resist corrosion and can handle sterilization. The right material depends on the fermentation process and the substances involved.

The Three-Agitator Configuration Advantage

A customized fermenter with three multi-bladed agitators is a game-changer. It’s great for industrial settings where quality and yield matter most.

Fluid Dynamics in Multi-Agitator Systems

Fluid dynamics in a fermenter with three agitators are better than single or dual ones. The extra agitator boosts mixing efficiency. This ensures nutrients and microorganisms are evenly spread in the broth.

This leads to a more consistent and better-quality product.

Comparative Advantages Over Single and Dual Agitator Designs

The three-agitator setup has clear benefits over single or dual designs. It offers a stronger mixing action. This is key for handling thick broths or sensitive microorganisms.

It also lets you adjust operational parameters more easily. This makes it easier to fine-tune fermentation conditions for different needs.

Optimal Spacing and Positioning Considerations

The right spacing and positioning of the agitators are key. They should be evenly spaced, with the bottom one close to the bottom of the vessel. This helps suspend solids and avoids dead zones.

The exact setup depends on the fermentation process. This includes the broth’s viscosity and the presence of solids.

Technical Specifications of Three Multi-Bladed Agitator Systems

It’s key to know the tech specs of three multi-bladed agitator systems for making efficient industrial fermenters. These systems are vital in many fermentation processes. They’re used in making pharmaceuticals, food, and drinks.

Dimensional Parameters and Scaling Relationships

The size of the agitators and how far apart they are are very important. These details affect how well they work. By scaling up or down, these systems can fit different sizes of fermenters. This keeps their performance consistent.

The size of the agitator compared to the fermenter is a critical factor. This ratio usually falls between 0.3 and 0.5. It depends on the specific needs and the level of agitation wanted.

Rotational Speed Ranges and Power Requirements

The speed at which the agitators spin and the power needed to move them are key. The speed can vary from 50 to 200 rpm. This depends on the broth’s thickness and the mixing needed.

The power needed is affected by the agitator size, broth density, and speed. Getting this right is important. It ensures the drive mechanism is the right size.

Torque Considerations and Drive Mechanisms

When designing the drive mechanisms, torque is a big deal. The torque needed to turn the agitators depends on several factors. These include the broth’s viscosity, agitator size and design, and speed.

Choosing the right drive mechanism is critical. It should handle the calculated torque and power well. It should also work reliably and need little maintenance.

| Parameter | Typical Range | Unit |

|---|---|---|

| Agitator Diameter | 0.3 – 0.5 | m |

| Rotational Speed | 50 – 200 | rpm |

| Power Requirement | 1 – 10 | kW |

| Torque | 100 – 1000 | Nm |

Schematic Analysis of Three Multi-Bladed Agitator Fermenter Design

The study of fermenters with three multi-bladed agitators shows the need for careful engineering in bioreactor design. It’s key to see how parts work together in the fermenter vessel.

Spatial Arrangement and Positioning

The way the three multi-bladed agitators are set up in the fermenter vessel is very important. The right spot ensures even mixing and avoids areas where stuff can get stuck.

It’s also important to have the right space between agitators and the walls of the vessel. This helps create the right flow of fluids.

Sealing Systems and Contamination Prevention

Sealing systems are key to keeping the fermenter system design clean. They stop contamination and keep the inside of the fermenter clean.

The seals need to be strong and work well, even under tough conditions inside the fermenter.

Integration with Vessel Internals

How the three multi-bladed agitators fit with other parts inside the vessel is important in fermenter system design. This setup helps make the fermentation process more efficient.

It’s important to think about how these parts work together. This helps improve performance and the quality of the product.

Engineering Considerations for Stainless Steel Fermenter Vessels

Building stainless steel fermenter vessels requires careful planning. Stainless steel is a top choice because it doesn’t rust easily and lasts a long time.

Material Selection and Compatibility

Choosing the right stainless steel is key. Grades 304 and 316L are common. Grade 316L is better for areas with chlorides.

It’s also important that the material works well with the fermentation process. The steel should not harm the product and can handle cleaning and sterilization.

Structural Integrity and Pressure Handling

The vessel’s strength is critical for safe use. It must handle the pressures and temperatures of fermentation.

Calculating the wall thickness and adding reinforcement are important. This helps prevent the vessel from collapsing or bursting.

| Stainless Steel Grade | Corrosion Resistance | Typical Applications |

|---|---|---|

| 304 | Good | General fermentation processes |

| 316L | Excellent | Processes involving chlorides or high acidity |

Process Control Systems for Multi-Agitator Fermenters

Process control systems are key for multi-agitator fermenters. They help monitor and control the process closely. This is important for getting the best yield and quality of the product.

These fermenters need advanced control systems because of their complexity. Advanced sensors and automation technologies track temperature, pH, dissolved oxygen, and agitator speed in real-time.

Automation and Monitoring Technologies

Automation in these fermenters uses computerized systems to manage process parameters. These systems can adjust agitator speeds, temperature, and more to keep conditions optimal.

Monitoring technologies, like sensors and probes, give real-time data on fermentation. This data helps make quick decisions and adjustments to improve the process.

| Parameter | Monitoring Technology | Control Mechanism |

|---|---|---|

| Temperature | Thermocouples | Heating/Cooling Systems |

| pH | pH Probes | Acid/Base Addition |

| Dissolved Oxygen | Oxygen Sensors | Air Flow Control |

Integration with Broader Production Systems

Process control systems for multi-agitator fermenters often link with broader production systems. This link allows for easy data sharing and coordination across production stages.

“The integration of process control systems with enterprise resource planning (ERP) systems has revolutionized the way fermentation processes are managed, allowing for real-time monitoring and optimization across the entire production chain.”

By linking process control systems with broader production systems, manufacturers can work more efficiently. They can cut costs and make products more consistent.

Customization Options for Different Fermentation Processes

Different fermentation processes need special fermenter designs. The success of these systems depends on how well they are customized. This is true in many fields, like pharmaceuticals, food and drinks, and specialty chemicals.

Adapting Agitator Design for Varying Viscosities

The broth’s viscosity affects the agitator’s work. For thick broths, customized agitator designs with better mixing are key. This ensures everything mixes well and nothing settles. For thin broths, less stirring is needed to avoid harming the cultures.

Modifications for Aerobic vs. Anaerobic Processes

Aerobic and anaerobic fermentation have different needs. Aerobic processes need good oxygen flow, so agitators with better aeration are needed. Anaerobic processes, needing little stirring, use special seals to keep out oxygen.

Industry-Specific Customization Requirements

| Industry | Customization Requirement | Benefit |

|---|---|---|

| Pharmaceuticals | High-precision temperature control and sterile conditions | Ensures product purity and compliance with regulatory standards |

| Food and Beverage | Customized agitator designs for viscous products | Improves product consistency and reduces processing time |

| Specialty Chemicals | Corrosion-resistant materials and coatings | Enhances durability and reduces maintenance costs |

Knowing these customization options helps industries make their fermenter system design better. This leads to more efficiency, productivity, and quality in products. The industrial fermenter market keeps growing. It’s driven by the need for tailored solutions for different fermentation needs.

Troubleshooting Common Issues in Multi-Agitator Systems

Multi-agitator systems are complex and need regular checks to work well. Troubleshooting helps avoid downtime and keeps the fermentation process consistent and high-quality.

Mechanical Failures and Preventative Measures

Mechanical problems can happen due to wear, bad installation, or lack of upkeep. It’s key to check and fix agitator parts like seals and bearings often. A good maintenance plan can lower the chance of these issues.

| Component | Inspection Frequency | Maintenance Action |

|---|---|---|

| Seals | Weekly | Inspect for wear, replace as needed |

| Bearings | Monthly | Lubricate, inspect for wear |

Process Performance Issues and Remediation

Issues like poor mixing or contamination can hurt product quality. Changing agitator speed or design, or improving cleaning, can fix these problems. Keeping an eye on how the system is working helps find and solve these issues fast.

Alignment and Balancing Challenges

Getting agitators right is key for them to work well and last longer. If they’re not aligned, they can vibrate more, wear out faster, and not work as well. Regular checks and tweaks keep the bioreactor design running smoothly.

By tackling these common problems early, operators can keep their multi-agitator systems running smoothly. This means better product quality and less time lost in fermentation equipment design.

Industry Applications of Three-Agitator Fermenters

Three-agitator fermenters are used in many industries because they are efficient and can be customized. They can be adjusted to fit the needs of different manufacturing processes. This makes them very useful in various fields.

Pharmaceutical and Biotech Applications

In the pharmaceutical and biotech fields, these fermenters are key for making complex biological molecules. They help control the environment needed for growing sensitive cells. Customization options help improve fermentation processes, leading to better yields and quality.

Companies like Pfizer and Merck use these fermenters to make vaccines and proteins. They can scale up production without losing quality. This is a big plus in these industries.

Food and Beverage Production

The food and drink industry also benefits from three-agitator fermenters. They are great for making fermented foods and drinks like yogurt, beer, and wine. These systems mix and aerate well, making products consistent and saving time.

Breweries, for example, use these fermenters to control fermentation conditions. This ensures their beers have the same taste every time.

Chemical and Specialty Product Manufacturing

In the chemical and specialty product sectors, these fermenters are used for making chemicals, enzymes, and more. They can be adjusted for different needs, making them versatile for many uses.

Experts say advanced fermenter technology has changed how specialty chemicals are made. It makes the process more efficient and cost-effective. This shows how important fermenter system design is for meeting industrial needs.

Economic Analysis and Return on Investment

Choosing a three-agitator fermenter design has big financial implications. It’s important to look at both the upfront costs and ongoing expenses. This helps ensure the system is financially sound.

Capital Investment Considerations

The cost of a three-agitator fermenter includes the vessel, agitators, and control systems. When deciding to invest, consider these key points:

- Equipment Costs: The price of the fermenter and its parts, like agitators and control systems.

- Installation Costs: The money needed for setting up the fermenter, including labor and materials.

- Validation and Compliance: The cost of making sure the fermenter meets all rules and standards.

Operational Cost Optimization and Efficiency Gains

Running a three-agitator fermenter costs money for energy, upkeep, and staff. Cutting these costs is key to making a profit. Here are some ways to do it:

- Energy Efficiency: Use energy-saving drives and design agitators to use less power.

- Maintenance Scheduling: Keep up with regular maintenance to avoid breakdowns and keep operations smooth.

- Process Optimization: Always check and tweak the fermentation process to get better yields and quality.

By looking closely at the costs and finding ways to save, businesses can see big improvements. This makes the investment in three-agitator fermenters worthwhile.

Conclusion: The Future of Fermenter Design

The future of fermenter design looks bright, with big steps expected in efficiency and product quality. As bioreactor design gets better, we’ll see more fermenters made for specific needs.

New designs in fermenter systems will focus on improving agitator setups. For example, the three multi-bladed agitator setup might become more common. It has shown to boost yield and quality.

As new fermentation techs become popular, the need for adaptable fermenter designs will rise. Companies will have to balance costs, scalability, and control to keep up with market demands.

Improving fermenter design is key for making top-notch products in many fields. By using the latest in bioreactor and fermenter tech, businesses can stay ahead and grow.